Introduction

With a strong foundation in AI and robotics, Pelican Robotics focuses on solving one of the most complex and labor-intensive challenges in fulfillment: pick-and-place tasks. Pelican Robotics’ mission is to deliver reliable, automated solutions that empower retailers to meet the rising demands of modern e-commerce and omnichannel fulfillment with efficiency and precision.

The Challenges: Enhancing Efficiency in Logistics Operations

The logistics sector faces growing challenges from increasing SKU variety, labor shortages, and fluctuating consumer demand. These trends place immense pressure on manual operations like depalletizing and palletizing, where speed and precision are critical. Pelican Robotics needed a solution that could reliably handle mixed-case loads while addressing these specific pain points:

- Labor Shortages: Challenges in hiring and retaining workers for repetitive, physically demanding tasks.

- Error-Prone Processes: Manual pick-and-place operations often led to mispicks, improper stacking, and reduced pallet stability, causing delays and product damage.

- Throughput Bottlenecks: Existing solutions struggled to keep up with rising throughput demands due to limited accuracy and slow processing times.

Previous attempts to solve these challenges relied on traditional vision systems that lacked the precision and adaptability required to identify and handle varying box sizes, positions, and orientations. These limitations led to operational inefficiencies, particularly in environments with inconsistent lighting or high SKU complexity.

The Solution: AI-Powered Palletizing Automation

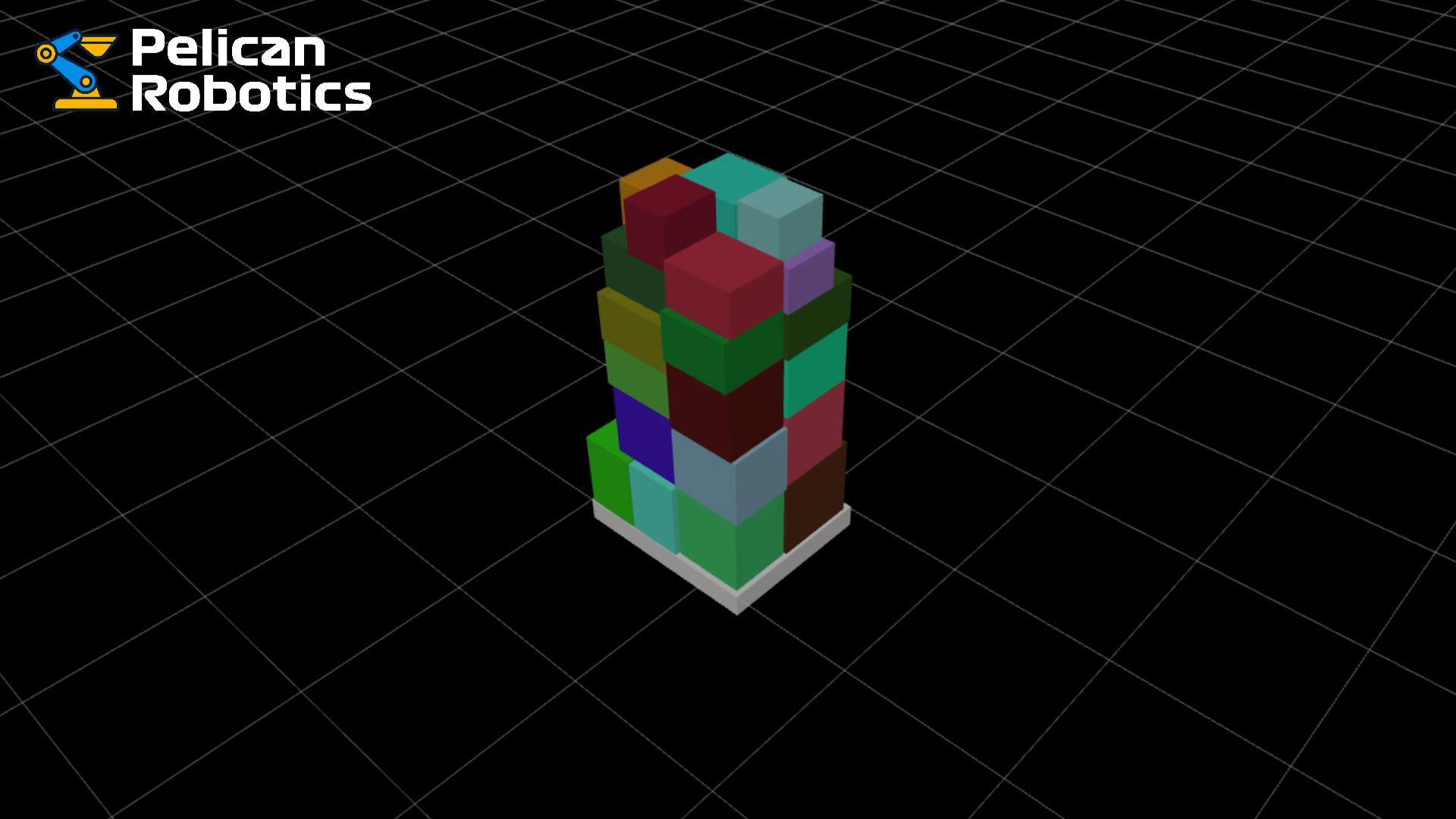

Pelican Robotics developed an innovative, AI-driven mixed-case depalletizing and palletizing system powered by Orbbec’s Femto Mega RGB-Depth Camera. This cutting-edge solution integrates seamlessly with warehouse workflows, combining Pelican’s advanced robotics and automation algorithms with Orbbec’s precision vision system to optimize efficiency at every step.

- High-Accuracy Volume Measurement: Orbbec’s Femto Mega cameras measure box dimensions with sub-millimeter accuracy, enabling precise calculations for pallet stacking and space utilization.

- Enhanced Object Recognition: The system identifies items regardless of size, position, or orientation, ensuring consistent performance even with mixed SKUs or challenging layouts.

- Optimal Stacking Algorithms: AI-driven algorithms optimize pallet configurations for stability and space efficiency, reducing damage during transport and increasing load density.

The system’s closed-loop design allows for continuous operation, automating both depalletizing and palletizing tasks in a compact footprint to maximize throughput and ROI.

Benefits and Outcomes

The integration of Orbbec’s Femto Mega 3D cameras has delivered measurable improvements in Pelican Robotics’ automated solutions:

- Increased Throughput: The system processes up to 1,000 cases per hour, significantly reducing cycle times compared to manual processes.

- Improved Accuracy: Achieved over 95% accuracy in SKU identification, significantly reducing mispicks and errors.

- Labor Efficiency: Reduced reliance on manual labor, allowing operators to focus on higher-value tasks while improving workplace safety.

- Cost Savings: Reduced product damage and delays, leading to an average 15-20% cost reduction for pilot users.

Future Prospects

Pelican Robotics envisions expanding this advanced depalletizing and palletizing solution to other areas of logistics and warehouse management, including automated unloading, put-away systems, and order picking. Innovations in AI and 3D vision technology, such as dynamic obstacle recognition and adaptive decision-making, are paving the way for next-generation robotics that can handle even greater complexity in warehouse environments.

Conclusion

Pelican Robotics is committed to redefining the future of warehouse automation by leveraging AI-driven robotics and advanced vision systems. By partnering with Orbbec, they have created a solution that not only addresses today’s challenges but also lays the foundation for scalable, efficient, and reliable automation in the years to come.